Any1 Choco’s Approach (Part 2):About Our Process – How is it different from traditional chocolates?

Everything you need to know about chocolate and Any1 Choco’s unique approach to the chocolate making process.

A New Technology That Will Transform Chocolate Making!?

In this article, we will explore Any1 Choco’s chocolate-making process.

For starters, how are traditional chocolates made?

At Any1 Choco, we create chocolates that can be enjoyed by anyone, with anyone.

This article will look into the differences between Any1 Choco and traditional chocolate-making processes.

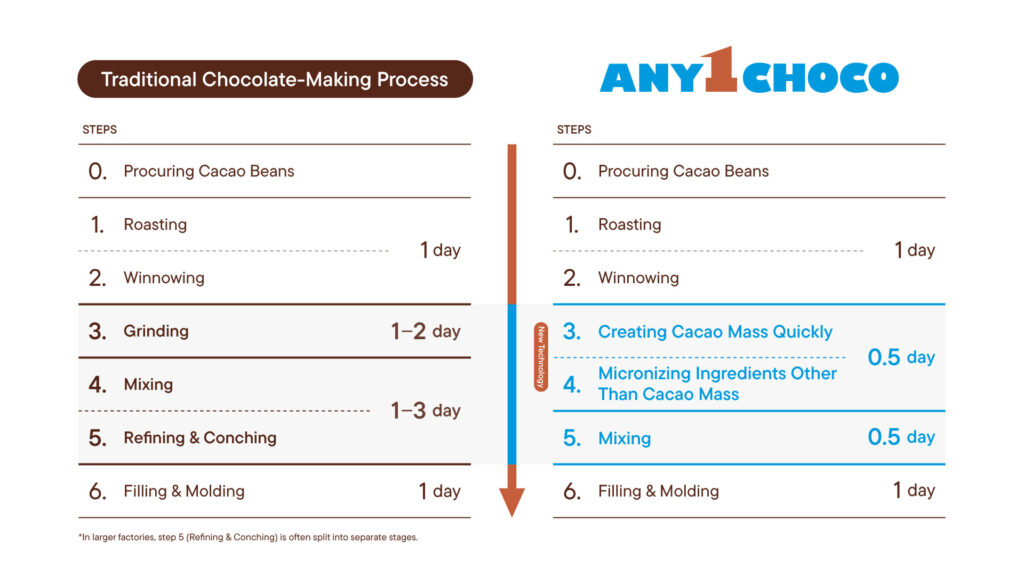

Let’s take a close look at the basic steps for making chocolate, following the diagram on the left side below.

Making chocolate begins with preparing the raw ingredient, cacao beans.

1. In chocolate factories and patisseries, the cacao beans are sorted and then roasted using a roaster set at 100–140°C. This roasting process brings out the distinctive aroma of the cacao.

2. The roasted cacao beans are cracked, and the shells – or cacao husks – are separated and removed. The remaining inner part is called cacao nibs.

3. These cacao nibs are then ground into a liquid paste using a machine. This paste is known as cacao mass.

4. Then, sugar, whole milk powder, and cocoa butter are mixed into the cacao mass. The sugar and whole milk powder particles are still coarse at this stage. While the mixture is somewhat fluid, it’s still rough, gritty, and not yet in the chocolate form.

5. To refine this mixture, the coarse particles are finely ground and gradually reduced in size by kneading over time, forming the base of the chocolate.

6. The refined chocolate base is then tempered (temperature-controlled), poured into molds, and cooled. After it’s molded and packaged, it becomes the chocolate we’re all familiar with.

Among the many stages of chocolate making, the most important and labor-intensive is the kneading process in step 5. This step is known as “conching” and can take 12 to 72 hours. Although it requires a significant amount of time and effort, this process is essential for creating smooth-textured chocolate while maintaining its distinctive aroma.

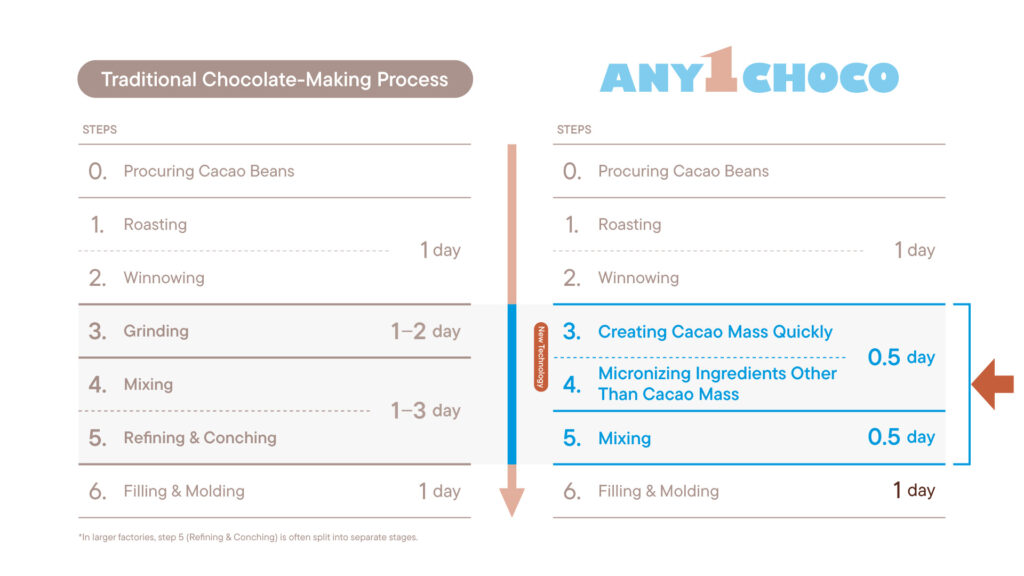

The central difference between this traditional process and the method used to make Any 1Choco chocolate lies in the time spent between steps 3 to 5, including conching. Our technology successfully cuts down on these lengthy processes.

Moreover, the chocolate still has a smooth texture despite skipping the conching process. Our approach maintains the same aroma and mouthfeel as chocolate made with traditional methods.

This dramatic reduction in production time has never been seen in the long history of chocolate-making.

What’s the secret behind Any1 Choco’s “New Technology?”

Why are we able to reduce production time so drastically?

There are two key features in our original processing method.

First, our cacao nibs are ground in a different manner from traditional methods.

Typically, chocolate manufacturers use various techniques to grind cacao nibs, such as applying force, using rollers, or machines inspired by the mechanics of millstones. In contrast, Any1 Choco uses original technology to finely process the cacao nibs into ultra-small particles. What’s remarkable is that this grinding process takes only around 30 minutes, compared to the one or two days typically required when using conventional methods.

Second, this technology isn’t limited to cacao nibs—it can reduce a variety of ingredients to particles as small as 10 microns.

At Any1 Choco, we pre-process sugar as well as white kidney beans and brown glutinous rice, which replace whole milk powder, into fine particles before mixing them with the cacao mass. Since almost all the ingredients are reduced to the same fine particle size, they blend uniformly and quickly without the need for conching. This shortens the production time in steps 3 to 5 while preserving the rich, deep flavor of the cacao.

Any1 Choco’s innovative method has genuinely astonished the chocolate industry, making it a groundbreaking leap in chocolate-making technology.

Quick, Safe, and Delicious

So, what exactly is this new technology for breaking down cacao nibs?

It’s a new Japanese technique based on hydrolysis technology. The technology was designed to break down ingredients like rice and vegetables to make their nutrients more absorbable and enhance their latent potential for easier use in food processing. This technology is already being applied to a wide range of food products. It also effectively sterilizes the ingredients during the decomposition process, including heat-resistant spores, contributing to more hygienic food production.

This technology can also unlock new potential in what was once discarded. For example, cacao husks, traditionally discarded after being separated from the cacao nibs, can now be repurposed in new ways, allowing us to fully utilize nature’s bounty.

Any1 Choco was born by applying this groundbreaking Japanese technology to chocolate-making.

Let’s take another look at the chart comparing the two approaches to chocolate-making. By completely reimagining steps 3 to 5, we’ve significantly reduced the time and space needed for the kneading process. This opens up exciting possibilities for small factories and shops to experiment with a wider variety of chocolate products using different ingredients.

Our goal is to bring excitement to both consumers and creators. Any1 Choco’s technology represents a new era in chocolate-making.

We hope to share this technology as a new alternative in the chocolate industry. We encourage interested pâtissiers to reach out!

In our next article, we’ll talk about the future of chocolate as shaped by Any1 Choco’s delicious chocolates and innovative technology.